Buying A Kiln

Hobby Kilns; Ceramic Kilns; Pottery Kilns;

Top Loading Kilns; Front Loading Kilns;

Home Kilns; Studio Kilns; School Kilns; Workshop Kilns;

Paint Your Own Pottery Kilns;

Kilns To Buy; Kilns For Sale;

We are not looking for a quick sale and invest in the longevity of our relationships.

We will support you through every aspect of using the kiln.

Kiln Price List . Kilns are listed on our webshop but please also email sales@countrylovecrafts .co.uk and ask for our KILN PRICE LIST. The document shows lots of information including prices, kilowatts, maximum temperatures, electrical supply, weight and dimensions (internal chamber and external). On page 2 there is a breakdown of the furniture sets included.

The importance of having a good kiln. Your kiln or kilns are the most important element (excuse the pun) of your business! Without a fully functioning kiln, you cannot trade. You will very quickly lose customers if their pieces are not fired correctly or are not ready on time. Size is important because you need to select a kiln that is neither too large for the amount of traffic it will see or too small to be constantly overloaded with work.

Kiln Firing. Every kiln can only cycle once every 24 hours. It takes 6-6½ hours to run the cycle (recommended for our products) and then a further 18 hours to cool down. You cannot speed up the cooling down process otherwise the pottery will crack.

Never bought a kiln before? Most customers that purchase a kiln from us have never used one before and are very nervous. We can provide honest advice to give you the support you need to use your new kiln with confidence. The kilns we stock have digital controllers. Firing your new kiln will be as easy as pressing one or two buttons.

Help to decide the right size: The size of kiln you need and your start-up costs will be dependent on (1) whether you are a home hobbyist, home business, shop, cafe or workshop (2) on the size of your start-up budget (3) how much of your business (or hobby) involves pottery painting e.g. for some business models it is 100% pottery painting; for others, it is a side-line (4) the size of business e.g. some studios will have 12 seats whereas others will have 30 seats. Based on these variables we can advise on possible kiln size options to buy.

Lots to Consider

If you're serious about buying a kiln, here's a checklist to help.

Kilns In Stock. We have some kilns in stock and if you need the kiln urgently these can be despatched on a next-day delivery (working day, not weekends). For kilns we don't have in stock, there is an average 2-3 week lead-time on a direct despatch agreement.

- Location: Please check the dimensions of all doorways and passages to ensure that the kiln can be placed in position (once a kiln has been delivered you will have to pay for a very costly return if it is too wide). Dimensions are listed on the kiln price list. The width is the narrowest part of the kiln (the kilns have a box that houses the wiring making it wider in some places).

- Electrical requirements: Please check your site can take the amperage and KW of the kiln (this is for either a home or business). A qualified electrician will need to confirm this. Again, once a kiln has been delivered it will be a very costly return if the kiln needs more power than the premises can provide. Amperage and KW are listed on the kiln price list. PLEASE NOTE: extension leads and electrical spur sockets are not suitable for the 13amp plug kilns as they weaken the power supply and ALL the power is needed to run the kiln.

- Kiln Deliveries: All deliveries are a door-to-pavement service. The courier will have a tail-lift and most drivers are willing to use a pallet truck to wheel the pallet as near to the final destination as possible. Don’t forget you will need to ensure you have the manpower on site to move the kiln (see weights listed on the price list for each model). The driver will not wait for you to unpack the kiln and nor will they take the pallet.

- Top firing temperatures: Some of the smaller kilns have a top temperature of 1200. If you want to fire stoneware, china or porcelain then this top temperature will be too low and you will need a kiln with a top firing temperature of 1300. Top firing temperatures are listed on the kiln price list.

- Help Deciding The Right Size: The size of kiln you need and your start-up costs will be dependent on (1) whether you are a home business or a static site (2) the size of your start-up budget (3) how much of your business involves pottery painting e.g. for some business models it is 100% pottery painting; for others, it is a side-line (4) the size of business e.g. some studios will have 12 seats whereas others will have 30 seats. Based on these variables I can advise on possible kiln size options to buy.

- Kiln Firing: Every kiln can only cycle once every 24 hours. It takes 6-6½ hours to run the cycle (recommended for our products) and then a further 18 hours to cool down. You cannot speed up the cooling down process otherwise the pottery will crack.

- Kiln Insurance: You may want to look at your business insurance too for adding the kiln. We have known of very few fires in decades of supplying kilns but they have all been down to user error e.g. people leaving flammable items on or around the kiln. If you do not tell your insurance company you have a kiln and there is a fire as a result of the kiln, your insurance will be invalidated. Just to reassure you, we represent global kiln manufacturers which outstanding safety features/records and the kilns we sell are located in schools and potteries around the world.

- Kin Programming: Kilns will not come pre-programmed and ready for use. To save you reading the manual and trying to understand the technical jargon, we have completed our very own step-by-step guide to programming the kiln - please note this is for using our products. If you buy bisque or clay elsewhere, you will need to ask your supplier for the recommended firing instructions as different clays, glazes and underglazes have different requirements.

Kiln

The biggest single expense for a pottery painting business is a kiln. Whilst there are second-hand options available online, some of these appliances are old/out of date with difficult to find spare parts and high running costs. A kiln is the most important part of your business. Without a running kiln, you will not be able to fire the pottery and a backlog will soon build up resulting in complaints.

Our Top Selling Kiln

For the last few decades, our Top-selling kiln (click on the red text for a link to our shop) has been a 60 litre 13amp plug-in kiln. It is the largest kiln you can buy on a household plug. Please note that you cannot use an extension lead with this appliance - extension leads weaken the power supply and the kiln will need maximum power to run.

The advantage of buying this kiln is that you will not need to pay an electrician to hard-wire your kiln (circa £300-600), the running costs are low, it is a great starter kiln size and can always be used as a second kiln (or sold) should you realise you need a larger kiln in the future.

Designed by Potterycrafts (a well-established UK manufacturer), this model is ideal for both a domestic set-up or a professional studio. Price includes: kiln, shelves, shelf risers (props) and delivery. We also sell a similar model by Nabertherm (a German manufacturer that sells kilns worldwide).

Click on our "Buying A Kiln" guide (above) for more information about buying kilns.

60 litre. Approximately 20-30 standard-sized mugs.

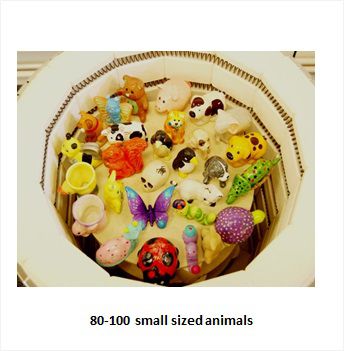

60 litre. Approximately 80-100 small-sized animals.

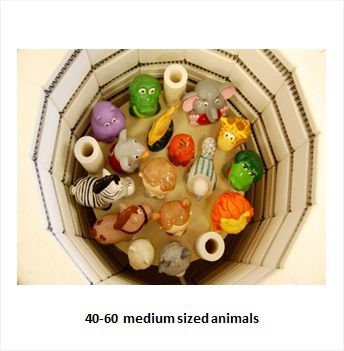

60 litre. Approximately 40-60 medium-sized animals.

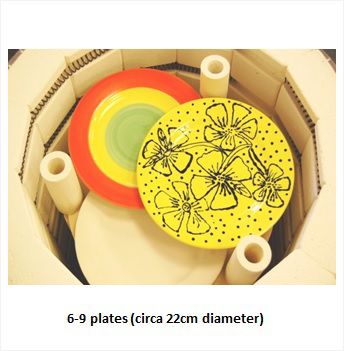

60 litre. Approximately 6-9 medium dinner plates (22cm)

The above figures are estimates and are dependent on the height and width of your shapes.

Firing A Kiln. You can only fire a kiln once a day. The programme we recommend for our bisque pottery lasts 6-6½ hours. It takes circa 18 hours for the kiln to cool. You cannot speed up the cool-down process because the pottery will most likely crack due to thermal shock. Therefore you can only do 7 firings each week. If you are worried about which size of kiln to buy, then please contact us.

Kiln Prices and Specifications. If you are interested in other size kilns then please email sales@countrylovecrafts.co.uk for a kiln pricelist. The document shows lots of information including prices, kilowatts, maximum temperatures, electrical supply, weight and dimensions (internal chamber and external chamber sizes). On page 2 there is a breakdown of the furniture sets included.

Urgent Kiln: If you need a kiln urgently, we have some kilns in stock and these can be despatched on a next-day delivery (working day, not weekends). For kilns we DON'T have in stock, there is an average 2-3 week lead-time on a direct despatch agreement.

Kiln Deliveries: All deliveries are a door-to-pavement service. For kilns that need hard-wiring, we would recommend you request a site survey from your electrician to ensure that the location can take the kilowatt and amps supplied. Do remember that if you order the wrong size kiln or the wrong electrical set up then it will be a very costly return (customers are responsible for the cost of returns).

Buying A Kiln From Us: It is in our interest that you glaze and fire your pottery successfully. We try to help where we can.

- We will provide written instructions on how to programme the kiln for our products so that you will not have to read (or try to understand) the kiln manual.

- We will provide ongoing phone, email and video support.

- If needed, we will provide video training for glazing and firing.

- We have over 30 support articles to help with troubleshooting imperfect firing results.

Costs of running a kiln: For our products, the firing will be typically 6-6½ hours up to a top temperature of 1020°c. We are using a "sample" rate of 12p per kW per hour and the kiln was a 3kw, 230v appliance:

- A=Kilowatt rating of the kiln (taken from data plate).

- B=Firing times in hours x 0.6 (since the kiln is only on full power towards the end of its cycle).

- C=Cost per kilowatt/unit (taken from your electricity bill)

- Formula: A x B x C = 3kw x 6.5 x 0.6 x 0.12 = £1.40 for a typical 6½ hour bisque firing.

If you operate from home, remember to contact your home insurance company to let them know you will be running a kiln from home.

Front Loading Kilns. We do have access to front loading kilns if this is your preference. However, please note that typically prices are circa £500 more expensive for front-loading kilns.

To install this Web App in your iPhone/iPad press

![]() and then Add to Home Screen.

and then Add to Home Screen.