Delayed Crazing on Pottery Ceramics

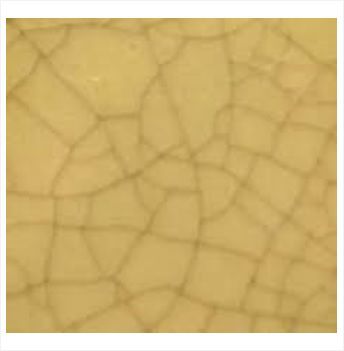

Hairline cracks on pottery

Crazing is a network of fine hairline cracks that appear on the glaze surface of a fired piece.

Crazed pottery or ceramics is not food-safe as the cracks can harbour bacteria or germs.

What is Crazing & Delayed Crazing On Pottery?

There are two types of crazing - immediate and delayed:

Delayed crazing: Sometimes occurs weeks or months later.

Immediate crazing: Can be seen (and sometimes heard in the form of a "pinging" sound) as soon as the kiln lid is opened.

Understanding why crazing occurs

-

Generally, crazing is considered a glaze defect (e.g the glaze is weaker than the un-crazed clay body surface).

-

Most things expand when hot and shrink/contract when cool. A clay body and glaze fuse together during firing. The aim is to get the right combination of expansion and contraction for a good glaze fit.

The difference between Crazing and Shivering:

-

If the glaze contracts more than the clay body during cooling then it will crack = CRAZING

-

If the clay body contracts more than the glaze, during cooling = SHIVERING

-

Interestingly, the time and temperature of the firing is extremely important to the process and will affect the type of crazing pattern that occurs.

Experiments to try in order to avoid crazing:

-

Do not over apply underglaze and glaze. Crazing can often be eliminated by applying a thinner coat of glaze, using less underglaze or a combination of both. Also consider:

-

Ensuring the transparent glazes are the correct viscosity before application.

-

Not over applying the transparent glaze (e.g. do not dip for too long or apply too many brush coats).

-

Ensuring that no more than three coats of underglaze are applied when decorating.

-

Ensure the bisque, glazes and underglazes are compatible. Your supplier should be able to confirm compatibility.

-

Do not over-fire or under-fire.

-

We sell Cone 04 bisque (earthenware clay that has been fired to 1060°c).

-

Most of our underglazes and transparent glazes are fired to Cone 06 (1000°c-1020°c).

-

Typically 1-3 coats of underglaze are used to decorate the bisque.

-

The viscosity of our clear glaze (Hobby Colorobbia) should be 19-24 seconds.

-

We recommend a firing schedule of 150°c per hour up to 600°c. From 600°c to 1020°c, we recommend a schedule of 2-3 hours e.g about 200°c per hour with a 20 minute soak at the end of the firing.

-

For larger bisque items and thicker wares please click on the link to see another recommended firing schedule and kiln loading techniques.

-

Crazing can also be reduced by increasing the firing time and slowing down the cooling. For example, try stretching out the firing cycle by a few hours during the last quarter of the glaze firing cycle. This will give the clay body the best chance to “tighten up” or reach its maturity, which will help in achieving a good glaze fit.

-

Do not open the kiln too soon e.g. ensure the wares are cool enough to handle without the use of kiln gloves.

-

Experiment by increasing the bisque firing a slightly higher cone temperature before decorating and glaze firing - half to one cone.

-

Experiment by increasing the glaze firing temperature slightly - half to one cone.

-

Frequently a combination of methods will work, depending on the severity of the craze problem. Being flexible in your thinking is important while evaluating the test results. If the results show that the craze lines moving further apart, continue with the corrections. If the craze lines are getting closer together, or staying the same, try something else.

Earthenware Ceramics

Another potential reason for crazing can happen after the ware has been put into use. If the clay body is porous (e.g earthenware clay) the fired item may absorb enough moisture to expand slightly. That expansion can be enough to upset the glaze-clay body fit and cause the glaze to craze. Continued heating and cooling of a piece e.g. ceramic tiles that are outside in all elements and mugs, bowls, teapots that are repeatedly used in the microwave, dishwasher or oven.

Under-fired or Over-Fired Earthenware Bisque

Sometimes under-fired bisque can cause crazing. Tests to determine whether earthenware is under-fired can often be inconclusive. However, a starting point (but not proof) may be the "tongue test". To do this, simply touch the bisque with your tongue. If the tongue does not stick to the bisque pottery then it is likely that the pottery has been OVER-FIRED. However, if your tongue sticks to the bisque and has a strong pinch, then the pottery has possibly been UNDER-FIRED. Please note this is not an accurate test - it is merely a guideline. Under-fired bisque can be repaired by re-firing the pottery to the correct programme (ramp time, soak and top temperature).

Sudden Temperature Changes and Prolonged Use

-

DO remember that our bisque is ceramic earthenware. Earthenware is porous and it will trap moisture. Therefore, extreme care should be taken as the pottery can get VERY HOT.

-

DO allow pottery to heat up gradually i.e. warm up teapots prior to use, warm pieces to room temperature after removing from refrigerator, don’t place cold wares in hot water.

-

DO allow hot pottery to cool down slowly i.e. don’t place hot wares in cold water.

-

DO NOT use domestic appliances if the piece is precious. Continual expansion and contraction of the piece will weaken the pottery over time and may cause cracking.

Glaze defeats and how these occur can be explained by Orton Ceramics in their helpful PDF document CLICK HERE to view.